To calculate pulley RPM‚ a formula is used‚ involving the diameter and RPM of the driving pulley‚ as well as the driven pulley’s diameter‚ found in pulley rpm calculation formula pdf documents․

Understanding the Basics of Pulley Systems

A pulley system consists of two or more pulleys connected by a belt or rope‚ with one pulley driving the other‚ and is commonly used in mechanical systems to transmit power or motion․ The driving pulley is typically connected to a motor or engine‚ while the driven pulley is connected to a load or machine․ Understanding the basics of pulley systems is essential for calculating pulley RPM‚ as it involves knowing the relationship between the driving and driven pulleys‚ including their diameters and RPM․ The pulley system’s design and configuration can affect the calculation‚ and using the correct formula‚ such as the one found in pulley rpm calculation formula pdf documents‚ is crucial for accurate results․ Proper understanding of pulley systems is necessary for various applications‚ including industrial machinery and power transmission systems‚ where precise calculations are required․ Pulley systems are widely used in many industries‚ including manufacturing and construction․

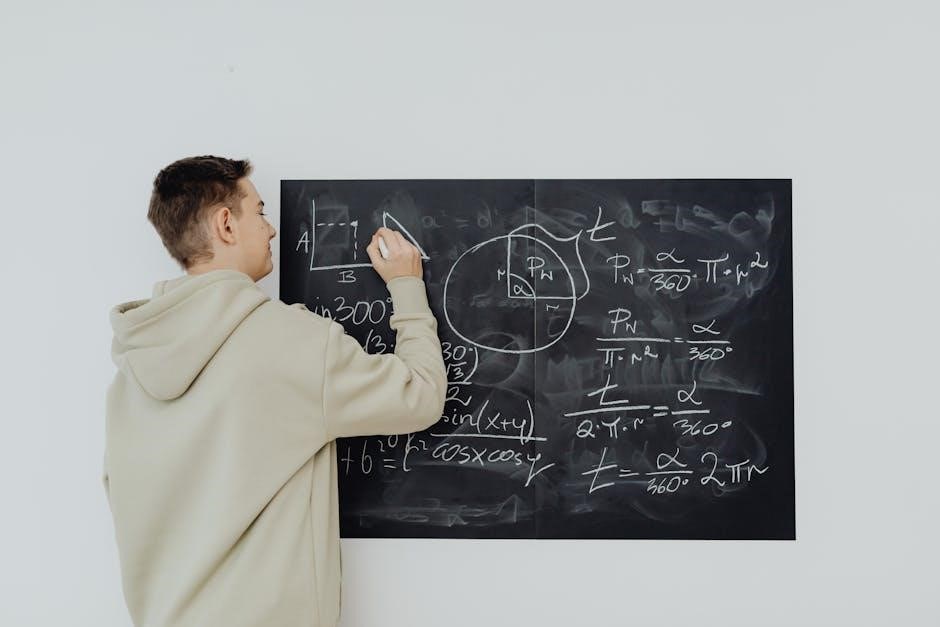

Formula for Calculating Pulley RPM

Calculating pulley RPM involves a specific formula found in pulley rpm calculation formula pdf documents for accurate results always online for reference and calculation purposes only․

RPM Calculation Using Pulley Diameter and RPM of Driving Pulley

To calculate the RPM of a driven pulley‚ the diameter and RPM of the driving pulley are required‚ as outlined in pulley rpm calculation formula pdf documents․

The formula involves dividing the product of the driving pulley’s diameter and RPM by the driven pulley’s diameter‚ resulting in the driven pulley’s RPM․

This calculation is crucial in determining the speed of the driven pulley‚ which is essential in various mechanical systems․

The pulley rpm calculation formula pdf provides a detailed explanation of this calculation‚ including the necessary steps and formulas to ensure accurate results․

By following the guidelines outlined in the pdf‚ users can easily calculate the RPM of a driven pulley using the diameter and RPM of the driving pulley․

The calculation process is straightforward and requires minimal mathematical knowledge‚ making it accessible to a wide range of users․

Power Transmission and Pulley Ratio

Pulley ratio affects speed‚ but not power‚ in power transmission systems‚ as explained in pulley rpm calculation formula pdf documents and related resources online always․

Effect of Pulley Ratio on Speed and Power

The pulley ratio has a significant impact on the speed of the driven pulley‚ with a larger driven pulley resulting in a lower speed‚ as discussed in pulley rpm calculation formula pdf documents․ This is because the pulley ratio determines the gear ratio‚ which in turn affects the speed of the output shaft․ On the other hand‚ the pulley ratio does not directly affect the power transmitted by the system‚ as power is a function of torque and speed․ However‚ the pulley ratio can indirectly affect power by changing the speed of the driven pulley‚ which can impact the overall efficiency of the system․ By understanding the effect of pulley ratio on speed and power‚ designers can optimize their systems for maximum efficiency and performance‚ using resources such as pulley rpm calculation formula pdf for guidance and calculation․

Calculating Driven Pulley RPM

Driven pulley RPM is calculated using the formula and pulley diameters‚ found in pulley rpm calculation formula pdf documents and online resources easily and quickly always․

Using the Formula: Driven Pulley RPM = (Motor RPM * Drive Pulley Diameter) / Driven Pulley Diameter

The formula for calculating driven pulley RPM is a fundamental concept in understanding pulley systems‚ as outlined in pulley rpm calculation formula pdf documents․ This formula allows users to determine the RPM of the driven pulley by using the motor RPM‚ drive pulley diameter‚ and driven pulley diameter․ By plugging in the values‚ users can easily calculate the driven pulley RPM․ The formula is widely used in various industries‚ including manufacturing and engineering․ It is essential to understand the formula and its application to ensure accurate calculations and efficient pulley system design․ The formula is also useful in troubleshooting and optimizing existing pulley systems․ With the formula‚ users can make informed decisions about pulley design and selection‚ leading to improved performance and productivity․ The calculation is straightforward and easy to apply․

Measuring Pulley Diameter and RPM

Accurate measurements of pulley diameter and RPM are crucial for calculations‚ using calipers and tachometers‚ as specified in pulley rpm calculation formula pdf guidelines always․

Importance of Accurate Measurements for Calculation

Accurate measurements of pulley diameter and RPM are essential for reliable calculations‚ as specified in pulley rpm calculation formula pdf documents․ The precision of these measurements directly affects the outcome of the calculation‚ making it crucial to use accurate tools and methods․ Using calipers and tachometers can help ensure precise measurements‚ reducing the risk of errors and inaccuracies․ By following the guidelines outlined in pulley rpm calculation formula pdf resources‚ individuals can ensure that their measurements are accurate and reliable‚ leading to more precise calculations and better decision-making․ This‚ in turn‚ can help optimize system performance‚ improve efficiency‚ and reduce the risk of mechanical failures‚ ultimately saving time and resources․ Accurate measurements are the foundation of reliable calculations‚ and their importance cannot be overstated in the context of pulley rpm calculation․

Belt Speed Calculation

Belt speed is calculated using the formula‚ found in pulley rpm calculation formula pdf‚ involving diameter and RPM‚ to determine the speed of the belt accurately always․

Using the Formula: Belt Speed = (Diameter of Pulley * RPM / 60) * (Pi / 2)

The formula for calculating belt speed is a fundamental concept in pulley systems‚ and it is widely used in various applications․ To calculate the belt speed‚ you need to know the diameter of the pulley and the RPM of the pulley․ The formula is then applied by multiplying the diameter of the pulley by the RPM‚ dividing the result by 60‚ and then multiplying it by the value of pi over 2․ This formula is commonly found in pulley rpm calculation formula pdf documents and is a crucial tool for engineers and technicians․ By using this formula‚ you can accurately determine the belt speed and ensure that your pulley system is operating efficiently․ The formula is a simple yet effective way to calculate belt speed․ It is widely used in industry and research․

Single Belt Transmission and Multiple Pulley Systems

Single belt transmission involves one driving pulley and one driven pulley in a system with multiple pulleys and belts for power transmission purposes always․

Calculating Pulley Speed and Diameter in Complex Systems

In complex systems‚ calculating pulley speed and diameter requires careful consideration of multiple factors‚ including the number of pulleys‚ belt type‚ and power transmission requirements․

To determine the speed and diameter of pulleys in these systems‚ engineers use specialized formulas and calculations‚ often found in pulley rpm calculation formula pdf documents․

These calculations involve understanding the relationships between pulley diameter‚ RPM‚ and power transmission‚ as well as the effects of belt slip and tension on system performance․

By applying these principles and formulas‚ engineers can design and optimize complex pulley systems for a wide range of applications‚ from industrial machinery to automotive systems․

The key to successful calculation is accurate measurement and data analysis‚ ensuring that the designed system meets the required specifications and performance standards․

No Responses